In today’s rapidly evolving world of technology, automation has become a key driver of efficiency and productivity. At the heart of this revolution lie two unsung heroes: sensors and actuators.

These essential components work tirelessly behind the scenes, enabling machines to interact with their environments and perform tasks with minimal human intervention. This blog post will explore sensors and actuators’ functions, types, and applications in various industries.

What are Sensors and Actuators?

Sensors

Sensors detect and measure physical properties or changes in their environment. They transform these measurements into electrical signals that a control system can process and analyze. Sensors play a crucial role in automation by providing real-time data about the state of a system, enabling it to make informed decisions and take appropriate actions.

Actuators

Conversely, actuators convert electrical signals into mechanical motion or other physical actions. They are responsible for executing the tasks determined by the control system based on the data provided by sensors. In essence, actuators are the “muscles” of an automated system, allowing it to interact with its environment and perform tasks.

Types of Sensors

Various sensors are available, each designed to measure specific physical properties. Some common types of sensors include:

Temperature Sensors:

- Purpose: Temperature sensors are designed to measure the temperature of their surrounding environment.

- Examples:

- Thermocouples: These sensors generate a voltage proportional to the temperature difference between two junctions of dissimilar metals.

- Resistance Temperature Detectors (RTDs): RTDs use the change in electrical resistance of materials like platinum to determine temperature.

- Thermistors: Thermistors are resistors whose resistance changes significantly with temperature variations, making them useful for precise measurements.

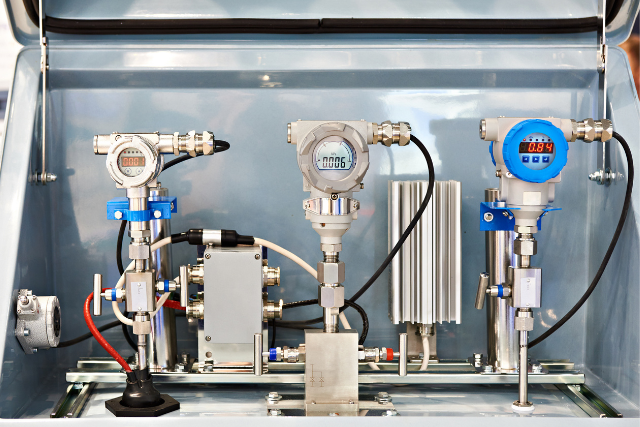

Pressure Sensors:

- Purpose: Pressure sensors are used to detect changes in pressure, which can be caused by gases, liquids, or other forces.

- Examples:

- Piezoelectric Sensors: These sensors generate an electrical charge when pressure is applied, commonly used in microphones and accelerometers.

- Strain Gauge Sensors: Strain gauges measure deformation caused by pressure and are used in applications like load cells.

- Capacitive Pressure Sensors: These sensors use changes in capacitance to detect pressure variations and are used in automotive applications, among others.

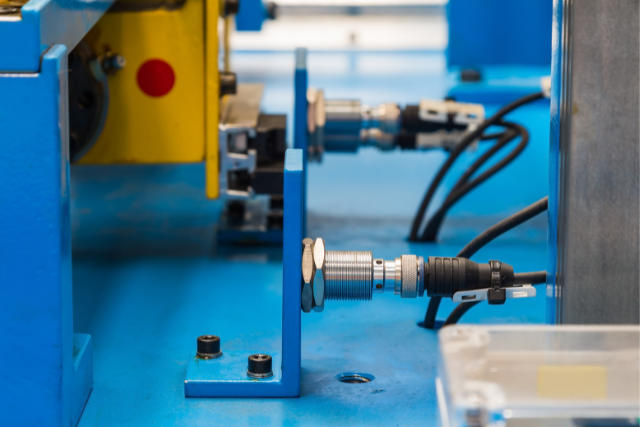

Proximity Sensors:

- Purpose: Proximity sensors detect the presence or absence of objects within a specified range without physical contact.

- Examples:

- Inductive Proximity Sensors: These sensors use electromagnetic fields to detect metal objects and are commonly used in industrial automation.

- Capacitive Proximity Sensors: These sensors work based on changes in capacitance and are often used in touchscreens and liquid-level detection.

- Ultrasonic Proximity Sensors: Ultrasonic sensors emit high-frequency sound waves and measure the time it takes to bounce back, suitable for object detection and distance measurement.

Light Sensors:

- Purpose: Light sensors measure the intensity of light in their surroundings.

- Examples:

- Photodiodes: Photodiodes convert incoming light into an electrical current, commonly used in light meters and optical communication.

- Phototransistors: These sensors are similar to photodiodes but offer current amplification, making them sensitive to low light levels.

- Photoresistors (LDRs): Light-dependent resistors change their resistance with varying light levels, used in applications like automatic streetlights.

Motion Sensors:

- Purpose: Motion sensors are designed to detect movement or changes in position.

- Examples:

- Accelerometers: Accelerometers measure acceleration and can detect tilt, vibration, and motion in devices like smartphones.

- Gyroscopes: Gyroscopes sense angular velocity and are crucial for stabilizing devices like drones and game controllers.

- Magnetometers: These sensors detect changes in magnetic fields and are used in compasses and navigation systems.

These sensors play vital roles in various industries and applications, from controlling the temperature of industrial processes to enabling the touch-sensitive screens on smartphones.

Understanding their principles and applications is essential for engineers and developers in various fields.

Types of Actuators

Like sensors, there are numerous types of actuators designed for various applications. Some common types of actuators include:

Electric Motors:

- Purpose: Electric motors are devices that convert electrical energy into mechanical motion. They are widely used in various applications requiring controlled rotation or linear movement.

- Examples:

- Direct Current (DC) Motors: DC motors operate on direct current and are often used in applications requiring precise speed control, such as robotics.

- Alternating Current (AC) Motors: AC motors run on alternating current and are found in appliances, industrial machinery, and HVAC systems.

- Stepper Motors: Stepper motors move in discrete steps and are commonly used in 3D printers, CNC machines, and automation systems.

Hydraulic Actuators:

- Purpose: Hydraulic actuators use pressurized fluid (usually oil) to generate force and motion. They are known for their high-force capabilities and are used in heavy machinery and industrial applications.

- Examples:

- Hydraulic Cylinders: These actuators use hydraulic pressure to extend or retract a piston, providing linear motion. They are prevalent in construction equipment and automotive braking systems.

- Hydraulic Motors: Hydraulic motors convert hydraulic energy into rotational motion and are used in applications like winches and conveyors.

Pneumatic Actuators:

- Purpose: Pneumatic actuators use compressed air to create force and motion. They are commonly used in applications where cleanliness and simplicity are essential.

- Examples:

- Pneumatic Cylinders: Pneumatic cylinders use compressed air to move a piston, providing linear motion. They are used in automation, packaging, and manufacturing.

- Pneumatic Motors: Pneumatic motors convert compressed air into rotary motion and are found in pneumatic drills and wrenches.

Piezoelectric Actuators:

- Purpose: Piezoelectric actuators utilize piezoelectric materials that change shape when subjected to an electric field, allowing precise motion control.

- Applications: In scientific instruments, piezoelectric actuators are used in nanopositioning stages, precision optics, and fine-tuning mechanisms.

Shape Memory Alloy Actuators:

- Purpose: Shape memory alloy actuators use materials that change shape when exposed to temperature changes. They are used for precise and compact motion control.

- Applications: Shape memory alloy actuators find applications in medical devices (e.g., stents), robotics, and aerospace systems where compact actuation is required.

Actuators are essential components in various engineering and industrial applications, allowing for the controlled movement of mechanical systems, tools, and devices.

Understanding the different types of actuators and their characteristics is crucial for designing and implementing systems that require motion control.

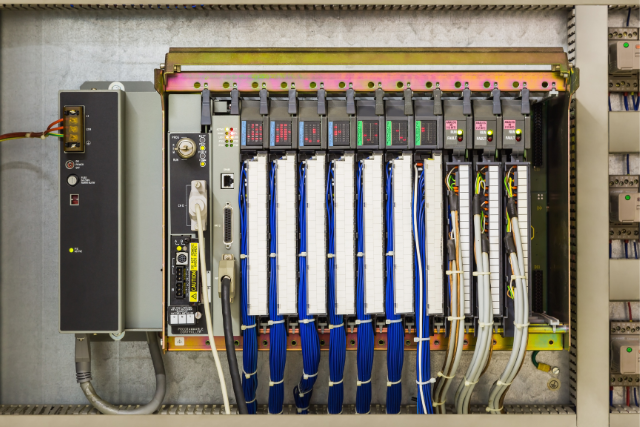

Applications of Sensors and Actuators in Automation

Sensors and actuators are used in a wide range of industries and applications. Some examples include:

- Manufacturing: In manufacturing, sensors and actuators monitor and control processes, ensuring product quality and consistency. Examples include temperature and pressure sensors in injection moulding machines and actuators in robotic arms for assembly lines.

- Automotive: Sensors and actuators play a crucial role in modern vehicles, enabling adaptive cruise control, lane departure warnings, and automatic braking. Examples include ultrasonic proximity sensors for parking assistance and electric motors for power steering.

- Healthcare: In healthcare, sensors and actuators are used in various medical devices and equipment. Examples include pressure sensors in blood pressure monitors and piezoelectric actuators in ultrasound machines.

- Smart Homes: Sensors and actuators are essential components of smart home systems, enabling features such as automated lighting, climate control, and security. Examples include motion sensors for lighting control and electric motors for automated window blinds.

- Aerospace: In aerospace, sensors and actuators are used to monitor and control various systems in aircraft and spacecraft. Examples include accelerometers for navigation and hydraulic actuators for flight control surfaces.

Conclusion

Sensors and actuators are the unsung heroes of automation, working tirelessly behind the scenes to enable machines to interact with their environments and perform tasks with minimal human intervention. As technology advances, we can expect to see even more innovative applications of sensors and actuators, further revolutionizing the world of automation and improving our lives in countless ways.