Just as a chameleon adapts to its environment, the world of medical device manufacturing is continually evolving, thanks in part to the flexibility offered by 3D printing materials.

You’re standing at the threshold of innovation with materials like TPU, known for its versatility; Silicone, heralded for its biocompatibility; and TPE, the ultimate hybrid.

These materials are not just altering the landscape—they’re redefining it. Understanding their unique properties and applications, you can unlock a world of possibilities in medical device production.

Let’s explore how these materials can transform your next project, and perhaps, the future of medical technology itself.

Key Takeaways

- TPU, Silicone, and TPE are top flexible materials for 3D printing patient-friendly medical devices.

- These materials offer a balance of durability, flexibility, and biocompatibility, essential for medical applications.

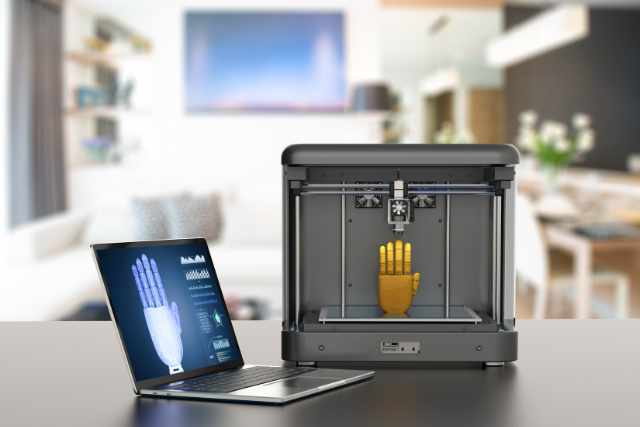

- Their versatility supports innovative medical device designs, from prosthetics to wearable health monitors.

- The sustainable nature of TPE, alongside the long-lasting properties of Silicone and TPU, aligns with future medical technology advancements.

TPU: The Versatile Performer

TPU, or Thermoplastic Polyurethane, stands out as a game-changer in 3D printing, offering unmatched flexibility and durability for medical devices.

When you’re moving into the world of creating medical devices with 3D printing, you’ll find TPU isn’t just another material; it’s your ally in innovation. Its ability to stretch without losing its shape means you can produce parts that need to bend or flex, like tubes or airways, without worrying about them breaking under pressure.

What’s more, TPU’s toughness ensures that the devices you create can withstand the wear and tear of everyday use. Imagine prosthetics that comfortably adapt to the wearer’s movements or braces that offer support while still allowing for a full range of motion. That’s the power of TPU.

But the benefits don’t stop at flexibility and durability. TPU’s compatibility with most 3D printers means you’re not limited by technology. You’re free to explore and create, pushing the boundaries of medical innovation.

With TPU, you’re equipped to tackle the challenges of designing medical devices that are not only effective but also patient-friendly. It’s time to embrace the possibilities and bring your ideas to life.

Silicone: Biocompatibility Champion

While TPU shines in flexibility and durability, silicone takes the spotlight when we talk about biocompatibility in medical devices. You’re likely seeking materials that not only perform but also ensure patient safety.

That’s where silicone stands out. Its exceptional compatibility with human tissue makes it a go-to for a wide range of medical applications. Here’s why silicone might just be your best bet for 3D printing medical devices:

- Inert nature: Silicone doesn’t react with bodily fluids and tissues, making it ideal for implants and prosthetics.

- Sterilization friendly: It withstands high temperatures and harsh sterilization processes without degrading, ensuring devices remain safe and effective.

- Customizable properties: You can tweak its hardness and flexibility, tailoring devices to specific medical needs.

- Longevity: Silicone maintains its properties over time, reducing the need for frequent replacements.

In a field where patient safety is paramount, choosing the right material is crucial. Silicone’s biocompatibility isn’t just a benefit; it’s a necessity.

As you explore the possibilities of 3D printing in medicine, remember that silicone offers a blend of performance and safety that’s hard to beat.

TPE: The Ultimate Hybrid

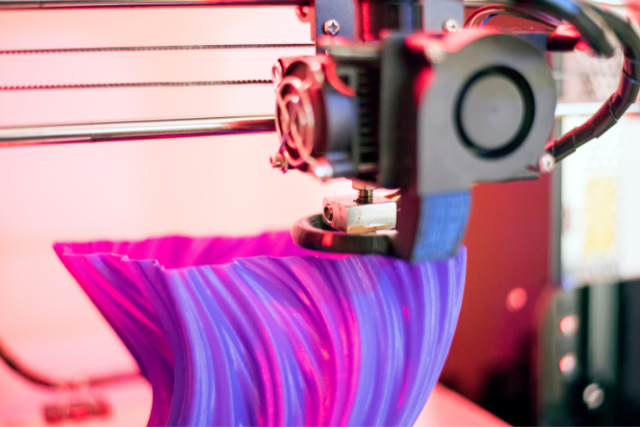

Flexibility meets durability in Thermoplastic Elastomers (TPE), offering a versatile solution for your medical device 3D printing needs.

Imagine a material that stretches like rubber but can be moulded and recycled like plastic. That’s TPE for you, blending the best of both worlds. It’s your go-to when you’re striving for devices that need to be tough yet tender, especially in sensitive applications.

TPE’s unique hybrid nature allows it to be soft and flexible, yet strong enough to withstand the rigours of daily use. This means you can create medical devices that are not just safe and reliable, but also comfortable for the end-user.

Whether it’s wearable devices that monitor health metrics without irritating the skin or soft, flexible tubing that conforms to the body, TPE has got you covered.

Moreover, its ability to be processed multiple times without losing its quality offers a sustainable edge. You’re not just choosing a material that’s kind for the body but also kind to the planet.

Enjoy the freedom to innovate without limits, knowing TPE supports your vision for more humane and environmentally conscious medical devices.

Conclusion

You’ve got three top-notch options for 3D printing in the medical field.

- TPU stands out for its versatility, making it a go-to for a range of applications.

- Silicone takes the crown for biocompatibility, ensuring patient safety is always a top priority.

- TPE combines the best of both, offering a hybrid solution that’s hard to beat.

Whether you’re innovating in prosthetics or developing wearable medical devices, these materials are set to revolutionize how you bring ideas to life.