In this article, I’ll take you on a journey through the exciting world of 3D printing.

I’ll explore cutting-edge materials, medical applications, and industrial manufacturing breakthroughs, all while uncovering the limitless potential this innovative technology holds.

Join me as we navigate the future possibilities of 3D printing and shed light on its role in sustainable and eco-friendly solutions.

Prepare to be amazed by the endless possibilities!

Table of Contents

Key Takeaways

- Material advancements have expanded the possibilities of 3D printing, allowing for the creation of complex and functional objects.

- 3D printing has revolutionized healthcare by creating implants, prosthetics, and organ models tailored to individual patients.

- In industrial manufacturing, 3D printing has revolutionized the production process by allowing for the creation of customized and complex parts at a lower cost, reducing waste, and speeding up the product development process.

- 3D printing promotes sustainability and eco-friendly solutions by minimizing waste, recycling and reusing materials, reducing transportation emissions, and enabling personalized and on-demand manufacturing.

Materials Advancements

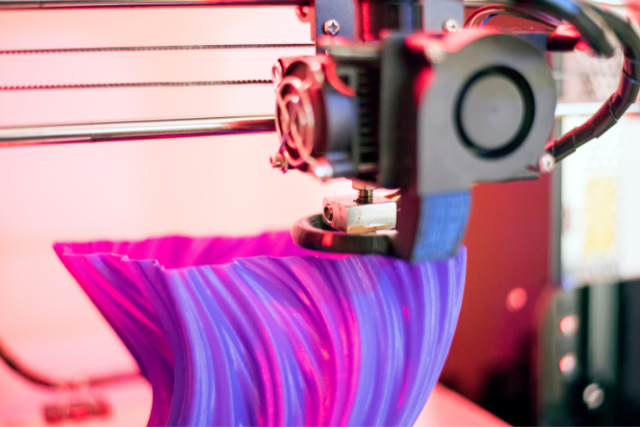

Advancements in materials have transformed the world of 3D printing. The field has witnessed significant developments in the materials used to create objects.

Traditional materials like plastics and metals are now supplemented with innovative options that can conduct electricity, withstand high temperatures, or mimic the texture of human skin.

These advancements expand the possibilities of 3D printing, allowing for the creation of complex and functional objects.

Whether you are a hobbyist or a professional, these material advancements provide the tools to bring your creative ideas to life in unimaginable ways.

Medical Applications

The advancements in 3D printing technology have revolutionized the healthcare industry, particularly in medical applications.

Patient-specific implants can be created using 3D printing, improving surgical outcomes and recovery times. Customized prosthetics are also easily produced, providing individuals greater mobility and independence.

3D printing is used to develop organ models for surgical planning and training, resulting in more precise procedures. Furthermore, the technology is being utilized to create drug delivery systems that release medication at controlled rates, enhancing treatment effectiveness.

3D bioprinting is also promising, as it aims to print living tissues and organs, potentially revolutionizing transplantation procedures.

These advancements have significantly benefited the medical field by offering personalized solutions, improving patient care, and pushing the boundaries of what is possible in healthcare.

Industrial Manufacturing

Exploring the latest advancements in 3D printing technology, let’s take a closer look at industrial manufacturing.

This application of 3D printing is revolutionizing the production process, allowing companies to create customized and complex parts at a lower cost.

By enabling the production of lightweight and durable components, 3D printing reduces the need for assembly and minimizes material waste. It also speeds up the product development process through rapid prototyping.

3D printing allows for creating intricate geometries and consolidating multiple parts into one component, enhancing efficiency and performance.

The potential for on-demand manufacturing further reduces inventory costs and enables just-in-time production.

Industrial manufacturing is undeniably benefiting from the advancements in 3D printing, creating a more agile and sustainable manufacturing landscape.

Sustainability and Eco-friendly Solutions

3D printing technology is playing a crucial role in promoting sustainability and eco-friendliness. 3D printing minimizes waste and reduces the environmental footprint by enabling precise material usage.

The ability to recycle and reuse materials in 3D printing promotes a circular economy and reduces the need for new resources. Moreover, localized production through 3D printing reduces transportation and associated emissions.

Also, optimizing designs and using lightweight materials in 3D printing helps decrease fuel consumption in transportation.

3D printing allows for personalized and on-demand manufacturing, reducing overproduction and excess inventory.

These sustainable practices contribute to a greener future, fostering a sense of belonging to a community that cares about the environment.

Future Possibilities

Explore the exciting future possibilities of 3D printing technology. This advancing innovation opens up countless opportunities for industries and individuals.

In the future, we can expect to see more complex and intricate designs effortlessly printed. Imagine the potential of printing fully functional organs for medical transplants or entire buildings with customized architecture.

Developing new materials will enhance the strength and durability of printed objects, revolutionizing manufacturing processes to be more efficient and cost-effective. The future of 3D printing holds immense promise, and we eagerly anticipate its advancements.

Frequently Asked Questions

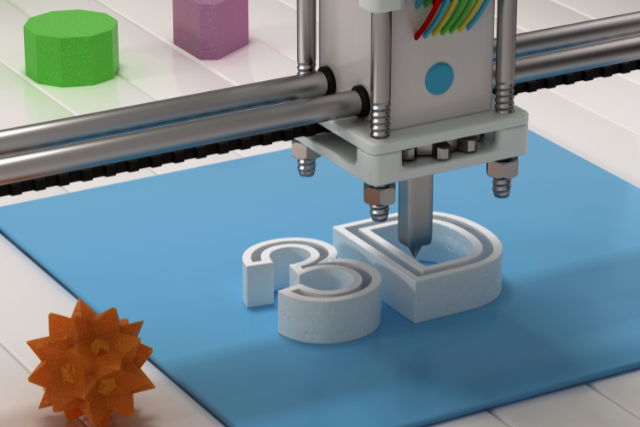

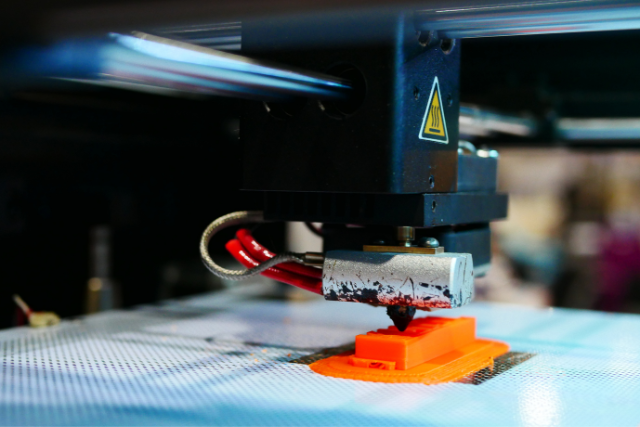

How Does 3D Printing Technology Work, and What Are the Basic Principles Behind It?

3D printing technology operates by building objects layer by layer using a digital model. It employs materials such as plastic or metal, which are melted and solidified to achieve the desired shape.

This process allows for the creation of intricate and precise designs with ease. It provides the freedom to explore various materials and experiment with different possibilities, making it an imperative tool in today’s ever-evolving manufacturing landscape.

What Are the Potential Risks and Challenges Associated With Using 3D Printing Technology?

Using 3D printing technology entails potential risks and challenges that must be considered. Awareness of these factors is crucial for ensuring safe and successful printing. Risks may include material toxicity, printer malfunctions, and copyright infringement. It is important to address these challenges to mitigate any potential negative consequences.

Are There Any Limitations or Constraints to the Size and Complexity of Objects That Can Be Printed Using 3D Printing Technology?

When utilizing 3D printing technology, there are limitations in the size and complexity of printable objects. These constraints vary depending on the specific printer and materials utilized.

How Affordable Is 3D Printing Technology for Individual Consumers or Small Businesses?

3D printing technology is increasingly accessible to individual consumers and small businesses. Affordable printers are now available, allowing you to enter the world of 3D printing. This technology opens up new possibilities and opportunities for creativity and innovation.

Are There Any Legal or Regulatory Considerations That Need to Be Taken Into Account When Using 3D Printing Technology?

Legal and regulatory considerations are crucial when utilizing 3D printing technology. These requirements ensure the safety of individuals, protect intellectual property rights, and prevent potential misuse. Staying informed and complying with the applicable laws and regulations is imperative to navigate this ever-evolving landscape.

Conclusion

The latest innovations in 3D printing technology have brought about a revolution in various industries.

Advancements in materials have expanded the possibilities for creating complex and durable objects.

Customized implants and prosthetics have improved patient care in the medical field. Moreover, industrial manufacturing has become more efficient and cost-effective with 3D printing.

There is a growing focus on sustainability and eco-friendly solutions, which have reduced waste and carbon footprint. With continuous advancements, the future of 3D printing holds limitless possibilities.