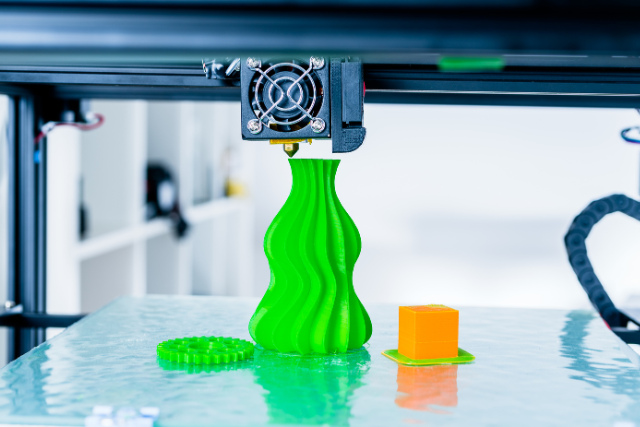

Ah, the thrill of buying your first FDM 3D printer – because who doesn’t want a machine that turns plastic spools into dreams?

But before you plunge into this transformative adventure, you have some homework. You’ll need to balance your budget against the seductive call of high-end features, understand the significance of print volume for your projects, and navigate the maze of filament types.

Don’t forget, the devil’s in the details like resolution, print speed, and software compatibility. Armed with a keen eye for these critical factors, you’re poised at the brink of a decision that could elevate your creative or professional work to new heights.

Let’s explore what lies beyond the surface, shall we?

Key Takeaways

- Determine your budget, considering the broad price range of FDM printers from basic to high-end models.

- Evaluate the print volume to ensure it matches the size of projects you plan to undertake.

- Decide on the filament type that best suits your printing needs, whether ABS, PLA or another material.

- Consider the printer’s resolution and layer height capabilities for achieving the desired quality and detail in your prints.

Setting Your Budget

Determining your budget is the crucial first step in selecting an FDM 3D printer that aligns with your printing goals and financial constraints. You’re not just buying a machine; you’re investing in a tool that’ll empower you to bring your ideas to life without breaking the bank.

FDM printers span a wide price range, from affordable options under a few hundred dollars to advanced models costing several thousand. It’s essential to balance financial feasibility and the features you need.

As you set your budget, consider what you aim to achieve with your printer. Starting with a more economical model might be wise if you’re dipping your toes into 3D printing.

These machines often have the necessary capabilities to tackle various projects, making them ideal for beginners.

On the other hand, if you’re looking to push the boundaries of your creative or professional work, investing in a higher-end printer could unlock new possibilities.

Understanding Print Volume

After setting your budget, it’s crucial to consider the print volume of your FDM 3D printer, as it directly impacts the size of objects you can create.

The print volume, the maximum build area, is measured in width, depth, and height. This dimension determines the largest object your printer can fabricate in a single run. Please don’t overlook this aspect, as it defines the scope of your projects.

If you aim for large-scale prototypes or want the freedom to print substantial objects, you’ll need a printer with a generous print volume. Conversely, a printer with a modest print volume might suffice if you focus on smaller, intricate items, potentially saving you money.

However, it’s wise to anticipate future needs. Opting for a slightly larger print volume than you envisage can save you from the limitations and frustration of outgrowing your printer too soon.

Understanding and selecting the right print volume is about accommodating your present needs and unlocking your creative potential. It’s about not letting the physical dimensions of your printer box in your imagination or ambitions. Choose wisely to ensure your pathway to innovation remains wide open.

Choosing Filament Type

Selecting the right filament type is a critical step in maximizing the performance and quality of your 3D prints. The filament you choose dictates not just the visual appeal but also the functional characteristics of your creations.

Here’s what you need to consider:

- Material Properties: Different filaments offer unique properties. For instance:

- PLA is biodegradable and easy to print, making it ideal for beginners.

- ABS provides higher strength and temperature resistance, which makes it suitable for more functional parts.

- PETG combines ease of printing with durability, balancing PLA and ABS.

- Application Requirements: Match the filament to your project’s needs. If you’re creating a decorative item, PLA’s wide range of colours and finishes might be your best bet. For parts that’ll undergo stress or need to withstand higher temperatures, ABS or PETG could be more appropriate.

- Printer Compatibility: Ensure your printer can handle the filament you choose. Some materials require higher extrusion temperatures or heated beds. Your printer’s specifications should guide your filament selection to avoid damage or poor-quality prints.

Choosing the right filament type empowers you to unleash your creativity while ensuring your projects are visually stunning and fit for purpose.

Get into the specifics of each material, and let your projects shine with the right foundation.

Resolution and Layer Height

When considering the resolution and layer height of your first FDM 3D printer, it’s crucial to understand that these factors directly impact the detail and smoothness of your printed objects.

The layer height is the thickness of each layer added during the printing process. Lower layer heights mean higher resolution prints, allowing for finer details and a smoother finish on your objects.

Here’s a simplified guide to understanding these terms:

| Layer Height (microns) | Resolution | Detail Level |

|---|---|---|

| 100 or less | High | Very Fine |

| 150 | Medium | Moderate |

| 200 | Low | Coarse |

| 250 | Very Low | Very Coarse |

| 300 | Lowest | Minimal |

Aiming for a printer that offers layer heights of 100 microns or lower will ensure you’re set up for quality results right from the start. It’s worth noting that lower layer heights can increase printing times. It’s a trade-off between detail and duration.

As a first-time buyer, you must decide what’s more important for your projects. Remember, liberation in creating means having the tools that match your vision’s demands.

Assessing Print Speed

Understanding the resolution and layer height of your FDM 3D printer sets the stage for exploring another critical aspect: print speed. It’s essential to grasp how print speed affects your projects.

This metric isn’t just about how fast your printer can push out models; it’s about balancing speed, quality, and patience.

Print speed is influenced by several factors, including the complexity of your design and the material you’re using. Here are key points to consider:

- Material Compatibility: Some materials print best at lower speeds, ensuring better adhesion and reducing warping.

- Detail vs. Speed: Higher speeds can lead to less detailed prints. If your project requires precision, be prepared to dial back the speed.

- Printer Capabilities: Not all printers are built the same. High-end models may boast faster print times without sacrificing quality, but they have a higher price tag.

Speed is liberating, allowing you to quickly churn out prototypes or final products. However, it’s a balancing act. You’ll need to weigh your desire for quick results against the need for detail and quality. Remember, the fastest print doesn’t always mean the best print.

Nozzle Size Considerations

Considering the impact on print detail and duration, you must pay attention to the nozzle size of your FDM 3D printer. Nozzle size directly influences your printing capabilities, affecting the intricacy of the details you can achieve and the speed at which your prints are completed.

Opting for the right nozzle size isn’t just about finding a middle ground; it’s about aligning your printing goals with the capabilities of your printer.

Here’s a quick guide to help you understand the implications of different nozzle sizes:

| Nozzle Size (mm) | Application |

|---|---|

| 0.2 – 0.25 | High-detail prints, slower printing speed |

| 0.4 (Standard) | Balanced detail and speed |

| 0.6 – 0.8 | Faster prints, lower detail |

Choosing a smaller nozzle size, like 0.2mm, allows you to print models with intricate details, perfect for miniatures or complex parts. However, bear in mind that these will take longer to print.

Conversely, a larger nozzle, such as 0.8mm, speeds up the printing process but at the expense of those finer details.

A 0.4mm nozzle strikes a good balance for most beginners, offering decent detail without significantly prolonging the print time.

This choice empowers you to explore a variety of projects, providing the liberation to learn and experiment with different settings and materials.

Connectivity Options

How do you plan to connect your FDM 3D printer to your devices and networks? In today’s interconnected world, ensuring your printer boasts the right connectivity options is key to a seamless, efficient printing experience.

It’s not just about plugging in and hoping for the best; it’s about choosing the connectivity that aligns with your workflow, preferences, and the devices you already use.

When considering connectivity options, keep these key points in mind:

- WiFi: Allows for wireless printing from anywhere in your network. It’s ideal to reduce cable clutter or operate your printer from different locations within the network range.

- USB: Offers a stable and direct connection to a single device. Perfect for those who prefer a straightforward, one-to-one connection without the potential issues of wireless connectivity.

- Ethernet: Ensures a reliable network connection, particularly in environments where WiFi is unstable or unavailable. It’s a great option for professional settings where network reliability is paramount.

Each connectivity option serves different needs and environments. Whether you’re aiming for the freedom of wireless printing, the reliability of a direct USB connection, or the stability of an Ethernet link, ensure your choice empowers your printing journey towards liberation and creativity.

Extruder Type Differences

Selecting the right extruder type is crucial for achieving your desired print quality and efficiency in FDM 3D printing.

Understanding the different types available and their unique benefits will empower you to make an informed decision that aligns with your creative aspirations and technical needs.

Firstly, single extruders are the standard in many entry-level printers. They’re straightforward, allowing you to print one colour or material at a time. It’s an excellent choice if you’re focusing on simplicity and cost-effectiveness.

However, a dual extruder might be your ticket to freedom if you’re aiming for more complex prints with multiple colours or materials.

With the ability to use two filament types simultaneously, dual extruders open up a world of possibilities for intricate designs and material combinations. This versatility, though, comes with a higher price tag and a steeper learning curve.

Selecting Software

Choosing the right software is crucial for transforming your 3D models into reality precisely and easily. When standing at the threshold of 3D printing, the software you select is your experience and the outcome of your creations.

It’s the bridge between your vision and the physical world. Therefore, diving into the world of FDM 3D printing demands carefully selecting software that aligns with your aspirations for liberation in creation.

Consider these key aspects:

- Compatibility: Ensure the software is compatible with your 3D printer model. A mismatch can limit your printer’s capabilities or render it unusable.

- User Interface (UI): A user-friendly interface is vital. You want software you can easily navigate, not something that feels like deciphering an ancient script.

- Features and Functionality: Look for software that offers a comprehensive set of tools. This includes support for various file formats, detailed model editing capabilities, and advanced slicing options.

Selecting the software isn’t just about getting your printer to work; it’s about unlocking its full potential. It’s about ensuring that your journey into 3D printing is as smooth and rewarding as possible, liberating your creativity and making your ideas tangible.

Entry Level Printers

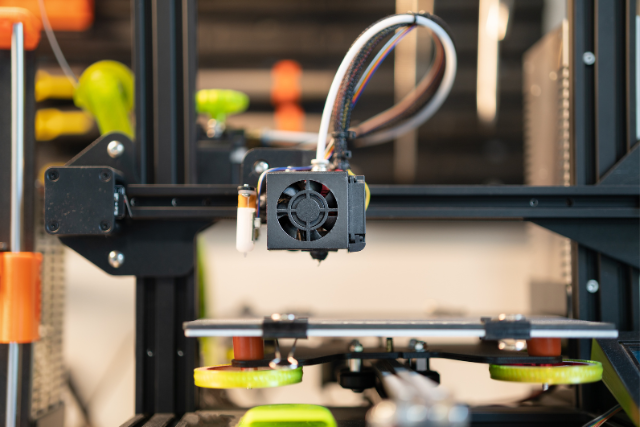

After ensuring your software aligns perfectly with your 3D printer, it’s crucial to explore the realm of entry-level printers, which offer a gateway to mastering FDM technology without overwhelming beginners.

Remember that your journey starts with identifying a printer that respects your budget while promising the freedom to create.

Entry-level FDM printers are your stepping stones in the vast universe of 3D printing. They typically come with a modest print volume, which, although limited, suffices for various projects and helps you understand spatial planning in three dimensions.

When selecting your first printer, consider the filament types it supports. Most entry-level machines work seamlessly with PLA and ABS, balancing ease of use and material strength for your initial forays.

The resolution and layer height capability of your printer are paramount. Look for options that offer 100 microns or lower to ensure the smoothness of your prints, a crucial factor for both functional prototypes and artistic endeavours.

Speed may not be your prime concern initially, but selecting a printer that balances quality with efficiency is key.

Enthusiast Grade Options

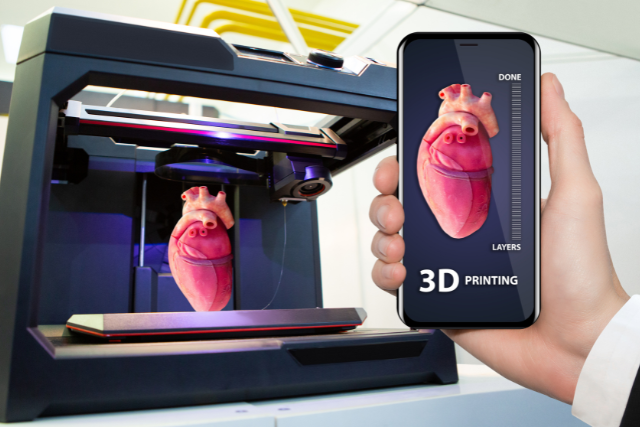

Exploring enthusiast-grade FDM 3D printers opens a gateway to advanced capabilities and precision, catering to users’ needs and ready to elevate their printing projects.

You’re not just buying a machine but investing in a tool to transform your creative visions into tangible realities. With this leap, several key factors become crucial to your decision-making process:

- Material Compatibility: Enthusiast printers often support a wider range of materials, from basic PLA to exotic composites. This versatility allows for experimentation and innovation in your projects.

- Enhanced Print Quality: Look for options that offer finer layer resolution and improved cooling systems. These features ensure smoother finishes and more detailed prints, pushing the boundaries of what you can create.

- Upgradeability: Many enthusiast-grade machines are designed to grow with you, featuring modular designs that allow for future upgrades. This adaptability ensures your printer remains relevant as your skills and needs evolve.

As you navigate through the plethora of options, remember that the best printer is the one that aligns with your ambitious goals. It’s not just about the specs; it’s about unlocking new possibilities and redefining the limits of your creativity.

With the right enthusiast-grade printer, you’re setting the stage for a journey of endless innovation and discovery.

Professional Grade Choices

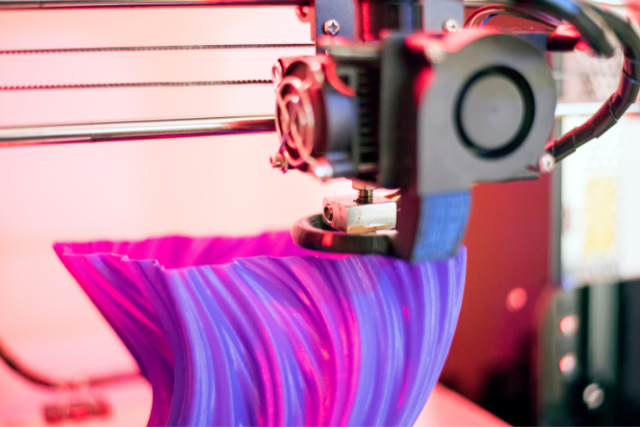

When you’re ready to elevate your 3D printing capabilities to professional levels, selecting a high-grade FDM printer becomes a pivotal decision in your creative journey.

It’s not just about having a tool; it’s about unlocking new realms of possibility. You’re looking for a machine that matches and anticipates your growing demands.

In your quest, consider the printer’s precision. Professional projects demand exceptional detail, so aim for printers boasting layer resolutions finer than 100 microns. These machines ensure your creations emerge with the smooth finishes and intricate details that set professional work apart.

Next, assess the printer’s material compatibility. You’ll want a printer that can handle diverse filaments, from standard ABS and PLA to more specialized materials like TPU and PEEK. This versatility is crucial for professional applications that require specific material properties, such as flexibility or thermal resistance.

Don’t overlook the importance of a robust software ecosystem. A professional-grade printer should be compatible with advanced slicing software, offering you extensive control over every aspect of the printing process. This includes support generation, print speeds, and material flow rates.

Lastly, evaluate the printer’s build volume. Bigger isn’t always better, but you’ll need enough space to accommodate your most ambitious projects without compromising quality.

Conclusion

Buying an FDM 3D printer for the first time requires careful consideration of several key factors. Setting a realistic budget, understanding the print volume you need, selecting the right filament, and considering resolution, speed, and software is paramount.

Whether starting with an entry-level printer, stepping up to enthusiast grade, or investing in professional options, making an informed decision ensures your 3D printing journey is both rewarding and successful.

Focus on the technicalities, and you’ll unlock limitless creative possibilities.