As sustainability gains prominence in 3D printing, enthusiasts and professionals are turning to eco-friendly materials that combine innovation with environmental responsibility.

Choosing suitable materials is crucial for reducing the ecological footprint of 3D printing projects, and several biodegradable options have emerged as frontrunners.

This blog explores three top biodegradable materials revolutionizing sustainable 3D printing: Polylactic Acid (PLA), algae-based filaments, and recycled wood materials.

1. Polylactic Acid (PLA)

Polylactic Acid, commonly known as PLA, is a bioplastic derived from renewable resources such as corn starch or sugar cane. Its popularity in the 3D printing community is due to its ease of use, eco-friendly nature, and versatility. Here’s why PLA stands out:

Biodegradability and Environmental Impact

PLA is biodegradable, meaning it can decompose into natural elements under specific conditions, leaving minimal residue. This characteristic makes it an excellent choice for those looking to minimize their environmental impact.

Unlike traditional plastics, which can persist in the environment for centuries, PLA products can quickly break down when composted industrially.

User-Friendly Characteristics

One of the primary reasons PLA is favoured in 3D printing is its user-friendly properties. It has a low melting point, which reduces energy consumption during printing.

This trait also helps prevent warping, making it ideal for producing high-quality prints with smooth finishes. Whether you are a beginner or a seasoned professional, PLA’s ease of use can significantly enhance your 3D printing experience.

Applications and Aesthetics

PLA is available in a wide range of colours and finishes, allowing for creativity in design. It is suitable for various applications, from prototyping to creating finished products such as toys, household items, and medical devices.

Its ability to blend aesthetic appeal with functionality makes it a versatile material in the sustainable 3D printing landscape.

2. Algae-Based Filaments

Algae-based filaments represent a groundbreaking advancement in sustainable 3D printing materials. These filaments are made by integrating algae biomass, a renewable resource, with biopolymers, resulting in an environmentally friendly and functional product.

Environmental Benefits

Using algae as a base for filament production offers numerous environmental benefits. Algae grow rapidly and can be harvested sustainably, making them a renewable resource.

Algae-based filaments are biodegradable and have a low carbon footprint, breaking down naturally without releasing harmful chemicals into the environment.

Unique Aesthetic and Applications

Algae-based filaments bring a unique, natural aesthetic to 3D-printed objects, often showcasing shades of green or earthy tones that reflect their origins.

This natural look can be particularly appealing for designers creating eco-friendly products with a distinctive appearance. The filaments are suitable for various applications, including art pieces, home decor, and educational tools.

Challenges and Considerations

While algae-based filaments are promising, they do come with specific challenges. The variability in the material properties, depending on the algae source and processing methods, can affect the consistency of prints.

However, ongoing research and development are addressing these issues, making algae-based filaments an increasingly viable option for sustainable 3D printing.

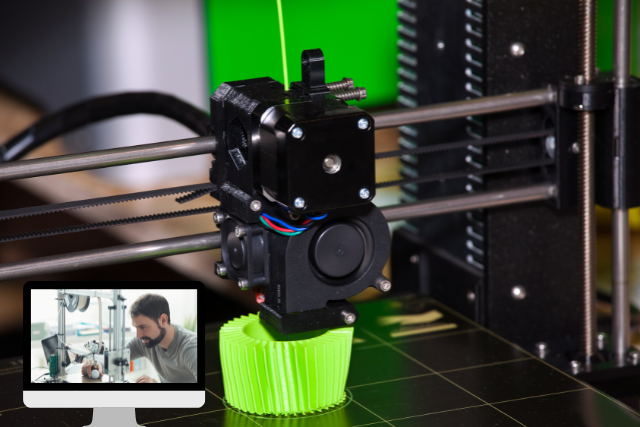

3. Recycled Wood Materials

Recycled wood materials are another innovative addition to the list of biodegradable options for 3D printing. These materials combine the natural appeal of wood with the benefits of sustainability and innovation.

The Circular Economy and Waste Reduction

Recycled wood filaments are typically made from post-consumer wood waste, such as sawdust or wood chips, combined with a biopolymer base like PLA.

This process reduces waste and supports the concept of a circular economy, where materials are reused and recycled, minimizing the extraction of raw resources and reducing environmental impact.

Aesthetic and Functional Benefits

Objects printed with recycled wood have a unique, natural appearance ranging from smooth and polished to more rustic and textured, depending on the desired finish.

These materials are lightweight yet durable, making them suitable for various applications, including furniture, home decor, and functional components. Using recycled wood in 3D printing opens new creative and sustainable design avenues.

Technical Considerations

Printing with recycled wood can be slightly more challenging than using standard PLA, as the wood particles can increase the filament’s brittleness. It may also require specific printer settings to achieve the best results. However, the effort is often worth it for the distinctive look and feel of the final products.

Conclusion

In conclusion, the shift towards biodegradable materials in 3D printing reflects a broader movement towards sustainability and environmental stewardship.

Polylactic Acid (PLA), algae-based filaments, and recycled wood materials offer unique benefits and challenges, making them suitable for different applications and levels of expertise.

By choosing these materials, you enhance your 3D printing projects and contribute to a greener and more sustainable future.

As technology and materials science continue to evolve, the options for sustainable 3D printing will only expand, offering new opportunities for creativity and innovation.

Whether you are an artist, designer, or engineer, incorporating these biodegradable materials into your work is a meaningful step towards reducing your ecological footprint and promoting environmental responsibility.

FAQs

What is Polylactic Acid (PLA)?

Polylactic Acid (PLA) is a biodegradable plastic made from renewable resources like corn starch. It is widely used in 3D printing for its ease of use and eco-friendly properties.

How are algae-based filaments made?

Algae-based filaments are made by combining algae biomass with biopolymers. This blend results in a biodegradable filament with a low carbon footprint, suitable for eco-friendly 3D printing.

What are the benefits of using recycled wood materials in 3D printing?

Recycled wood materials help reduce waste and support a circular economy. They provide a natural aesthetic and are lightweight and durable, making them ideal for various applications.

Are there any challenges associated with using biodegradable 3D printing materials?

Some challenges include the need for specific printer settings and the potential for variability in material properties, especially with algae-based filaments and recycled wood materials.

Why is sustainability important in 3D printing?

Sustainability in 3D printing is crucial for reducing environmental impact, conserving resources, and promoting responsible consumption. Biodegradable materials help minimize pollution and waste.

Can beginners use biodegradable materials like PLA in 3D printing?

Absolutely! PLA is particularly beginner-friendly due to its low melting point and ease of printing, making it an excellent choice for those new to 3D printing.