Isn’t it fascinating how AI is quietly revolutionizing the world of 3D printing? You’re now standing at the precipice of a new era where designing complex structures, streamlining production, and implementing predictive maintenance are becoming more streamlined.

With the power of AI, you can make real-time adjustments and push the boundaries of customization and personalization in ways previously deemed impossible.

This technological synergy is enhancing the capabilities within various industries and setting the stage for unprecedented innovations.

Let’s explore how this fusion is paving the way for a future where the possibilities are as limitless as our imagination.

Key Takeaways

- AI-driven design tools enhance creativity and optimize materials for industries like aerospace and healthcare.

- Through predictive maintenance, AI minimizes downtime and increases the efficiency of 3D printing processes.

- Real-time adjustments and error correction by AI improve the quality and efficiency of 3D prints.

- AI enables unparalleled customization in manufacturing, offering personalized solutions in healthcare, automotive, and beyond.

Enhancing Design Complexity

With AI’s help, you can now push the boundaries of creativity by designing complex structures that were once deemed impossible to create with traditional methods. Imagine intricate designs that flow like water yet stand as strong as steel.

AI algorithms analyze and optimize these designs, ensuring they’re breathtaking and structurally sound. The limitations of human calculation or traditional design constraints no longer confine you. This is freedom in creation, a true liberation for your imagination.

You see, AI doesn’t just suggest the ordinary; it ventures into realms of design that you might not have considered. It’s like having an infinitely creative partner who speaks the language of possibility.

The impact is profound, from lightweight yet durable materials for aerospace to bespoke, ergonomic designs in the medical field. Your designs can now be as complex and unique as the ideas in your head, seamlessly brought to life.

This revolution in design complexity isn’t just about aesthetics but functionality, efficiency, and innovation. You’re at the forefront of a creative renaissance, where the only limit is your imagination. Welcome to the future of design, where AI is your tool, and the world is your canvas.

Streamlining Production Processes

Now that you’ve unlocked the potential of designing intricate and complex structures with AI let’s explore how it also streamlines production processes, making your creations come to life more efficiently than ever.

With the help of AI in 3D printing, you’re crafting with precision and stepping into a realm where every production phase is optimized for speed and efficiency.

| Aspect | Impact of AI |

|---|---|

| Material Usage | Reduces waste by precisely calculating the amount of material needed for each print. |

| Print Speed | Optimizes printing parameters to increase the speed without compromising quality. |

| Error Detection | Identifies and corrects issues in real-time, preventing faulty prints. |

| Workflow Automation | Automates mundane tasks, allowing you to focus on innovation and design. |

Embracing AI in your 3D printing endeavours does more than streamline production; it liberates you from the constraints of traditional manufacturing, giving you the freedom to explore, create, and innovate like never before.

This is how you break free from the old ways and usher in a new era of manufacturing efficiency and creativity.

Predictive Maintenance Integration

Imagine your 3D printer can predict its breakdowns before they happen. With AI-driven failure detection, it’s not just a dream; it’s becoming a reality.

This means you can proactively replace components, drastically reducing downtime and keeping your production line moving smoothly.

AI-Driven Failure Detection

Integrating AI into 3D printing operations allows for the early detection of potential failures, ensuring smoother and more efficient production processes. You’re no longer just reacting to problems; you’re anticipating them. This proactive stance is a game-changer, significantly reducing downtime and waste.

Key benefits include:

- Real-time monitoring of print jobs to identify anomalies that could indicate a looming failure.

- Data analysis from past prints to predict future issues allows you to intervene before they escalate.

- Streamlined operations by keeping your printers running optimally, avoiding the cost and frustration of unexpected breakdowns.

Proactive Component Replacement

With predictive maintenance, you can proactively replace components before they fail, significantly enhancing your 3D printing operations. This approach saves time and reduces the risk of unexpected downtimes, keeping your projects on schedule and within budget.

Here’s a glance at how this works:

| Component | Warning Sign | Action Taken |

|---|---|---|

| Print Head | Inconsistent extrusion | Replace head |

| Filament Feeder | Slippage detection | Adjust tension |

| Build Plate | Uneven prints | Re-level plate |

| Cooling Fans | Increased noise | Replace fans |

| Software | Lag in response | Update/Upgrade |

This table showcases the power of predictive maintenance. You’re not just fixing problems; you’re staying ahead, ensuring your 3D printing journey is as smooth and uninterrupted as possible.

Real-Time Adjustments Capability

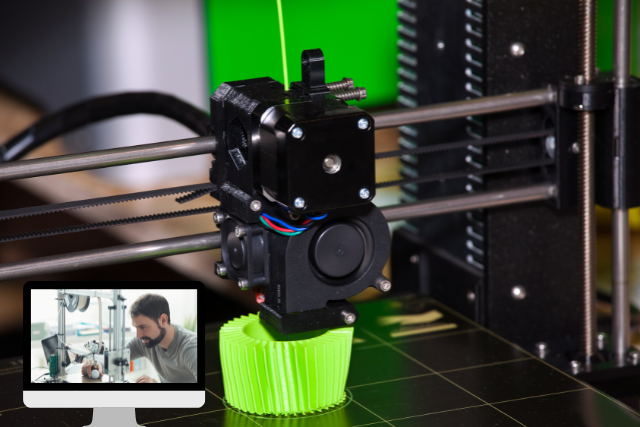

One game-changer in combining AI with 3D printing is the technology’s ability to make real-time adjustments during printing.

This capability isn’t just a minor improvement; it’s revolutionizing how objects are printed, offering you a level of freedom and precision that was previously unthinkable.

With AI’s help, your printer can detect and correct errors on the fly, ensuring the final product is as close to perfection as possible.

Here’s how this feature is shaking things up:

- Error Detection and Correction: If something goes off-course, AI algorithms can spot the error immediately and adjust the printing parameters to correct it, often without human intervention.

- Material Efficiency: By reducing waste through precise adjustments, you save materials and contribute to a more sustainable printing practice.

- Time Savings: No more do-overs. The AI’s ability to adjust in real-time means that your print will likely come out right the first time, saving you time and frustration.

This leap towards smarter, more autonomous 3D printing is freeing you from the constraints of traditional printing methods, allowing for more innovation and creativity in your projects.

Customization and Personalization

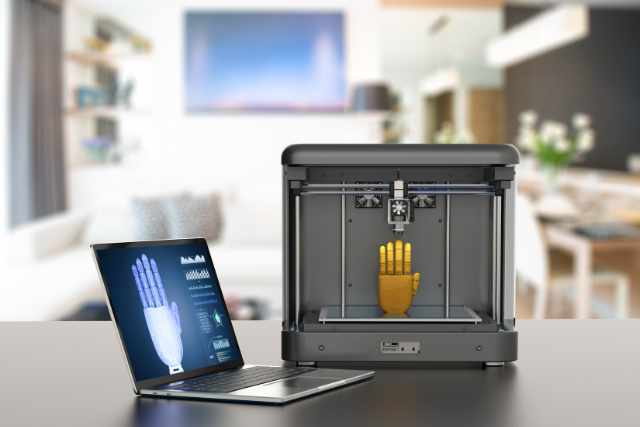

You can now tailor every aspect of your project to meet specific needs and preferences, opening a world of customization and personalization opportunities. Imagine creating something that’s not just a product but a piece of you, reflecting your unique style, needs, and desires. This is the freedom AI and 3D printing bring to your doorstep.

You’re no longer confined to what’s available on the shelf. With these technologies, if you can dream it, you can make it.

Picture designing a phone case that perfectly fits your hand, decorated with a pattern that tells your story, or custom-fit earphones that match the contour of your ear like a glove. This isn’t just about aesthetics but functionality tailored to you.

This level of personalization extends beyond just personal gadgets. Think about bespoke furniture that fits your living space as part of the original blueprint or custom tools designed to tackle specific tasks with unprecedented efficiency.

The power of AI and 3D printing is in your hands, offering a new dimension of personal expression and practicality. The only limit is your imagination.

Impact on Various Industries

As you explore the impact of AI and 3D printing across various industries, you’ll find healthcare making strides with customization, manufacturing experiencing efficiency leaps, and the automotive sector speeding up innovation.

These advancements are reshaping how products are designed, made, and delivered, offering unprecedented opportunities for growth and development.

Let’s examine how these changes are setting new standards and what they mean for the future of these sectors.

Healthcare Customization Advances

In healthcare, AI and 3D printing technologies are revolutionizing how personalized treatments and medical devices are created, offering unprecedented customization to meet individual patient needs. This leap forward means you’re no longer stuck with one-size-fits-all solutions but can now benefit from:

- Prosthetics tailored to your body’s unique contours, enhancing comfort and functionality.

- Custom dental implants that fit perfectly, improving recovery time and overall oral health.

- Personalized organ models are used for surgical preparation, significantly reducing risks involved in complex procedures.

These advancements aren’t just about improving outcomes; they’re about placing you at the centre of your healthcare journey.

Harnessing the power of AI and 3D printing, the medical field is moving towards a future where treatments are effective and uniquely yours.

Manufacturing Efficiency Boost

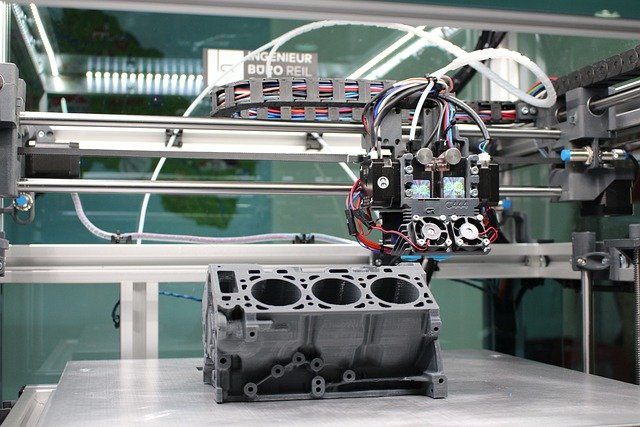

Beyond healthcare, AI and 3D printing are also transforming the manufacturing landscape, significantly boosting efficiency across various industries.

You’re witnessing a revolution where the fusion of these technologies enables companies to produce goods faster, cheaper, and with greater precision than ever before. Imagine reducing waste and optimizing resource use, all while speeding up production times.

That’s the power at your fingertips. This synergy isn’t just about improving the bottom line; it’s about pushing the boundaries of what’s possible, offering you the chance to rethink design, production, and delivery processes.

From aerospace to consumer goods, businesses find that incorporating AI-driven 3D printing into their workflows isn’t just a choice—it’s becoming necessary to stay ahead in today’s competitive market.

Automotive Innovation Acceleration

AI and 3D printing are rapidly accelerating innovation within the automotive industry, reshaping how vehicles are designed and manufactured. You’re witnessing a revolution breaking the mould, making the impossible possible. Here’s how:

- Customization at Your Fingertips: Tailor your ride to your heart’s content, from unique aesthetics to optimized functionalities.

- Speed Like Never Before: Slash development times, getting new models from concept to showroom floor faster than ever.

- Sustainability in the Driver’s Seat: Embrace eco-friendly materials and processes, driving towards a greener future.

This leap forward isn’t just about sleeker cars; it’s about empowering you to demand more from the vehicles you drive and the world you inhabit.

Get ready because the road ahead is looking thrillingly different.

Conclusion

AI is changing the game in 3D printing by making designs more complex and production smoother. It predicts when machines need fixing and adjusts prints in real-time, allowing for unique, personalized items.

This revolution isn’t just about gadgets; it’s reshaping industries from healthcare to fashion. Imagine having products tailored for you, made efficiently and with incredible precision. That’s the future AI and 3D printing are building together, making the once impossible possible.