Welcome to the cutting-edge world of industrial automation powered by Artificial Intelligence (AI). In recent years, the integration of AI technology has revolutionized the landscape of manufacturing and production, paving the way for a new era of efficiency and innovation.

From predictive maintenance to intelligent control systems, AI’s role in modern industrial automation reshapes how industries operate, optimize processes, and deliver products to the world.

Table of Contents

The Rise of AI in Industrial Automation

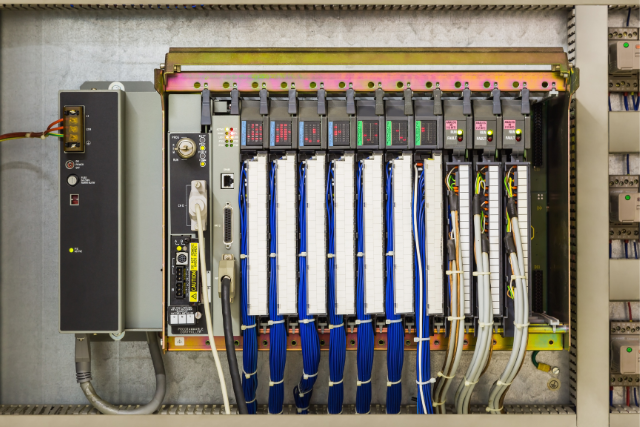

Since the first assembly lines and programmable logic controllers (PLCs), industrial automation has come a long way. Today, AI is at the forefront of this evolution, enabling manufacturers to optimize their processes, reduce costs, and improve product quality.

Several factors are driving the integration of AI in industrial automation:

- Increased computing power: The exponential growth has made it possible to process large volumes of data and run complex AI algorithms in real time.

- Advancements in machine learning: Machine learning, a subset of AI, has made significant strides in recent years, allowing machines to learn from data and make predictions or decisions without explicit programming.

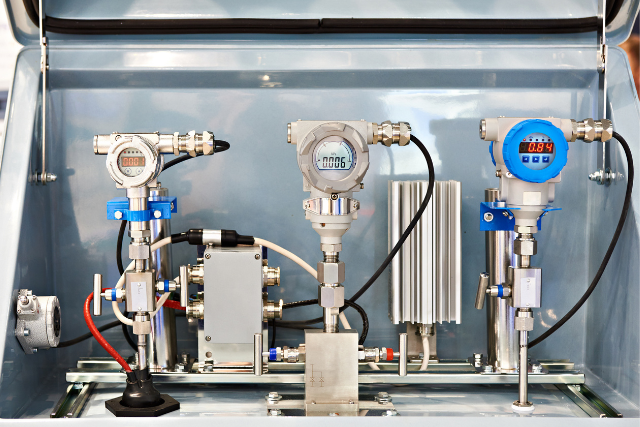

- Availability of data: The proliferation of sensors and connected devices in the industrial environment has led to an explosion of data, providing valuable insights for AI algorithms to analyze and act upon.

- Reduced costs of sensors and hardware: The decreasing costs of sensors, cameras, and other hardware components have made it more feasible for manufacturers to adopt AI-powered automation solutions.

What is Smart Manufacturing?

Smart manufacturing refers to integrating advanced technologies, data analytics, and automation into the manufacturing process to optimize production efficiency, improve product quality, and reduce operational costs. It is a key component of the broader concept of Industry 4.0, which represents the fourth industrial revolution characterized by the digital transformation of industries.

Key elements of smart manufacturing include:

- Internet of Things (IoT): The IoT enables the interconnection of machines, devices, and sensors, allowing them to communicate and exchange data. This connectivity facilitates real-time monitoring and control of manufacturing processes, leading to better decision-making and improved efficiency.

- Big Data and Analytics: Smart manufacturing systems generate vast amounts of data from various sources, such as sensors, machines, and production lines. Advanced analytics tools process and analyze this data, providing valuable insights for optimizing production processes, predicting equipment failures, and enhancing product quality.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms are employed to analyze data, identify patterns, and make predictions. These technologies enable smart manufacturing systems to learn from experience, adapt to changing conditions, and optimize processes autonomously.

- Robotics and Automation: Advanced robotics and automation technologies perform repetitive tasks, increase precision, and reduce human error. This improves productivity and frees human workers to focus on more complex and creative tasks.

- Digital Twin: A digital twin is a virtual representation of a physical asset or process that can be used to simulate, predict, and optimize performance. By creating digital twins of manufacturing processes, companies can test new strategies, identify bottlenecks, and optimize production without disrupting actual operations.

- Additive Manufacturing: Also known as 3D printing, additive manufacturing enables the creation of complex parts and products by adding material layer by layer. This technology allows for greater design flexibility, reduced waste, and faster production times.

- Cybersecurity: As manufacturing systems become increasingly interconnected and reliant on data, ensuring the security of these systems is crucial. Robust cybersecurity measures are necessary to protect sensitive information and prevent disruptions to production.

Smart manufacturing offers numerous benefits, such as increased efficiency, reduced waste, enhanced product quality, and greater flexibility. Companies can create more sustainable and competitive manufacturing operations by leveraging advanced technologies and data-driven insights.

The Synergy of Robotics and AI

Robots have long been a vital part of industrial automation, but with the integration of AI, they have become even more capable and adaptable. AI-powered robots can learn from their surroundings and make autonomous decisions, making them ideal for tasks that require flexibility and precision.

The advent of collaborative robots, popularly known as ‘cobots’, marks a significant milestone in robotics and AI synergy. Unlike traditional robots that operate in isolation, cobots are designed to work hand-in-hand with humans.

Their built-in sensors and AI algorithms ensure that they can safely operate alongside their human counterparts, intuitively understanding when to assist, when to pause, and when to take the lead. This results in heightened productivity and reduced risk of workplace injuries.

The Journey to Industry 4.0

Characterized by the seamless integration of digital technologies and Artificial Intelligence (AI) into industrial processes, Industry 4.0 is a transformative force poised to revolutionize manufacturing and production. At its core lies the vision of “smart factories,” where machines, products, and humans collaborate harmoniously, ushering in a new era of efficiency and innovation.

The Foundation of Industry 4.0: Connectivity and Data Exchange: At the heart of Industry 4.0 lies the concept of connectivity, where machines, devices, and systems communicate and share data in real time. This interconnectedness facilitates the exchange of vital information, enabling a holistic production process view. Sensors embedded in machines capture and transmit data, providing valuable insights that drive decision-making and process optimization.

The Role of Artificial Intelligence in Industry 4.0: AI catalyzes Industry 4.0, infusing intelligence and adaptability into the production ecosystem. With AI algorithms analyzing vast datasets, smart factories can predict maintenance needs, identify inefficiencies, and optimize workflows. The seamless collaboration between AI and human operators results in a dynamic production environment where tasks are executed precisely and accurately.

Creating Smart Factories: In the journey to Industry 4.0, traditional factories are transforming into smart factories. Here, physical production and digital technologies convergence allows for real-time monitoring, tracking, and control. The production floor becomes an intelligent ecosystem where autonomous machines collaborate with human workers to achieve exceptional productivity.

Self-Optimizing Production Systems: The Heart of Industry 4.0: A defining aspect of Industry 4.0 is the emergence of self-optimizing production systems. These systems continuously analyze data under the control of adaptive algorithms to find bottlenecks, inefficiencies, and areas for improvement. With this knowledge, smart factories make real-time adjustments, optimizing production processes. As a result, productivity soars, waste diminishes, and overall efficiency reaches unprecedented heights.

Realizing the Promise of Reduced Waste and Enhanced Sustainability: Industry 4.0 promises a more sustainable future. By eliminating wasteful practices and optimizing resource usage, smart factories contribute to reduced environmental impact. AI-driven predictive maintenance helps extend the lifespan of machinery, minimizing electronic waste. Additionally, data-driven decision-making leads to leaner processes, conserving energy and materials.

The Human-Machine Collaboration: Empowering the Workforce: In the era of Industry 4.0, the role of human workers undergoes a profound transformation. Human operators become intelligent automation’s enablers rather than its victims. Empowered with AI-driven insights, they become more proactive decision-makers and creative problem-solvers. Smart factories foster a culture of continuous learning, upskilling the workforce to thrive in a technology-centric environment.

Challenges on the Road to Industry 4.0: While the promise of Industry 4.0 is alluring, its realization is not without challenges. The digital transformation necessitates significant investments in infrastructure, cybersecurity, and workforce training. Moreover, adapting legacy systems to integrate with cutting-edge technologies can be complex. However, overcoming these hurdles brings rewards that transcend efficiency, unlocking innovation and global competitiveness.

Empowering Human Workforce with AI

In the ever-evolving landscape of modern industrial automation, one concern often looms: will the rise of AI and automation replace human workers, rendering them obsolete? Contrary to these apprehensions, integrating AI into the workforce is proving to be a powerful enabler rather than a threat.

The emergence of AI as a collaborative partner is transforming industries, allowing human workers to harness their creativity, strategic thinking, and problem-solving skills like never before.

Automating the Mundane and Repetitive: One of the primary benefits of AI in the workplace is its ability to take on repetitive and mundane tasks that were once the domain of human workers. These tasks, though necessary, can be time-consuming and monotonous, leading to employee disengagement and reduced productivity.

With AI taking over these routine activities, human workers are liberated from the drudgery, allowing them to focus on tasks that require higher-level cognitive abilities.

Unleashing Creativity and Strategic Thinking: AI’s role as a digital assistant has unleashed a new era of creative problem-solving and strategic thinking among human workers. Freed from the burden of repetitive tasks, employees have the bandwidth to delve into more complex challenges, devise innovative solutions, and brainstorm ways to improve processes. This surge of creativity and ingenuity enhances overall workplace productivity and drives continuous improvement across industries.

Enhancing Job Satisfaction: As AI performs repetitive tasks, human workers find greater satisfaction in their roles. The feeling of being part of a dynamic and forward-thinking workplace that values their unique skills fosters a sense of purpose and fulfillment. Employees are more likely to feel invested in their work when they can contribute to meaningful projects and collaborate with AI-driven tools to achieve outstanding results.

Reducing Workplace Injuries: In industries where safety is a primary concern, AI-powered automation has significantly minimized workplace injuries. Robots and machines powered by AI are now performing dangerous and hazardous tasks that once posed risks to human workers. This shift improves safety and allows human workers to oversee and manage operations from a safer distance, reducing the chances of accidents.

Upskilling and Professional Growth: Far from eliminating jobs, the collaboration between AI and human workers creates new opportunities for upskilling and professional growth. As AI takes over repetitive tasks, companies invest in employee training programs to develop new skill sets that complement AI-driven automation. This upskilling enhances employees’ value to their employers and equips them to adapt to the changing demands of the job market.

A Harmonious Future: The integration of AI into the workforce signals a harmonious future where human workers and machines complement each other’s strengths. Rather than replacing humans, AI empowers them to evolve, adapt, and thrive in a rapidly changing technological landscape.

With AI’s assistance, the quest to unleash the full potential of human ingenuity has only just begun. As industries continue to embrace this transformative partnership, the future of work is set to be more fulfilling, innovative, and collaborative than ever before. The possibilities are boundless, and the power to shape this future lies in the hands of human workers and the AI technologies they co-create.

Conclusion

As we journey through AI-driven modern industrial automation, we witness a transformational shift impacting every industry aspect worldwide. AI has become the catalyst for innovation, propelling manufacturing and production capabilities to unprecedented heights.

With continuous advancements in AI technology, the possibilities are limitless, and the future promises smarter, more efficient, and interconnected industrial ecosystems. Embrace the power of AI in modern industrial automation, for the future is now, and the possibilities are boundless.