Get ready to be amazed as we explore the five creative ways 3D printing transforms the fashion industry.

This innovative technology is revolutionizing how we create and wear fashion, offering endless possibilities for customization, sustainability, and intricate designs.

With rapid prototyping and a more inclusive approach, fashion is becoming accessible. Let’s examine the exciting ways 3D printing reshapes the fashion world.

Table of Contents

Key Takeaways

- Customization and personalization: 3D printing allows for unique and personalized designs, offering limitless possibilities for customization and self-expression in fashion.

- Sustainability and eco-friendly materials: 3D printing reduces the carbon footprint by using recycled or bio-based materials, optimizing material usage, and promoting a circular economy.

- Complex and intricate accessories: 3D printing creates unique and intricate designs for accessories, reshaping how we think about and design fashion accessories.

- Rapid prototyping and iterative design process: 3D printing accelerates the design process, reduces production costs, and facilitates faster development and refinement of designs, making fashion more accessible.

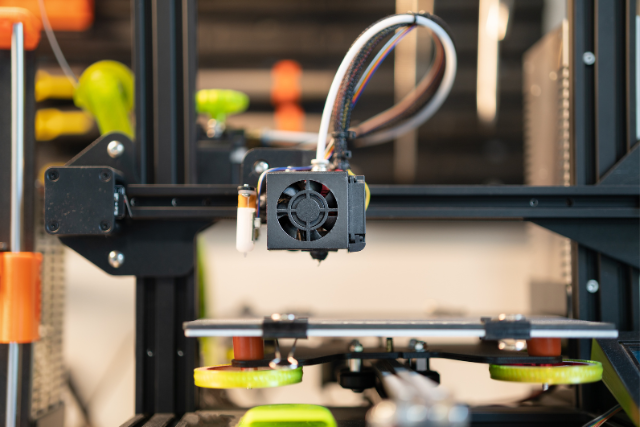

How Does 3D Printing Work?

The process of 3D printing involves several steps:

Step 1: Creating a 3D Model

The first step in 3D printing is creating a digital 3D model of the object using computer-aided design (CAD) software. The 3D model can be created from scratch or scanned from an existing object.

Step 2: Preparing the 3D Model

Once the 3D model is complete, it is prepared for printing. This involves checking the model for errors and ensuring it is suitable for 3D printing.

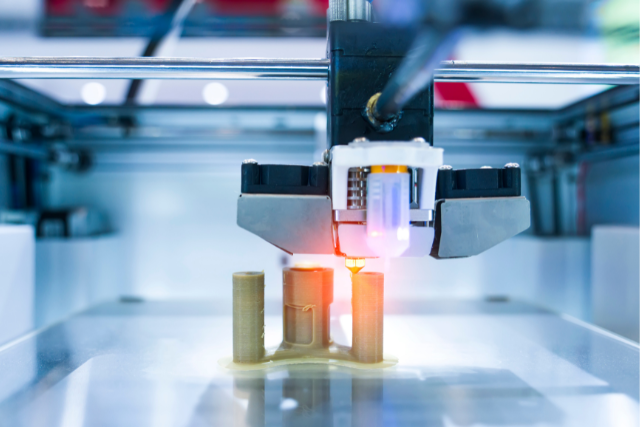

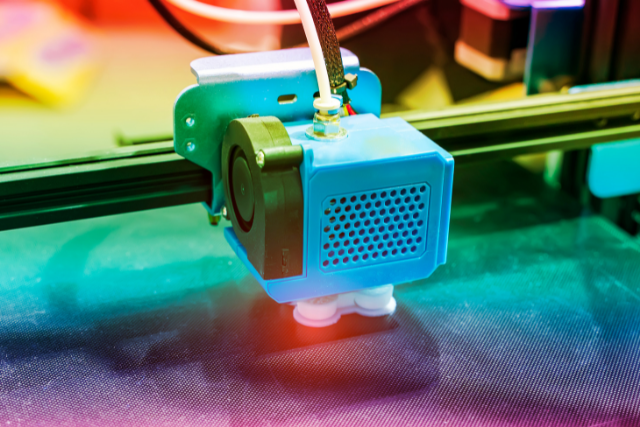

Step 3: Printing the Object

The 3D model is then sent to a 3D printer, which uses various materials to create the physical object. The printer builds the object layer by layer, using additive manufacturing.

Step 4: Post-Processing

Once the object is printed, post-processing may require removing any support structures or rough edges. The object may also be painted or finished to achieve the desired look.

Benefits of 3D Printing

There are several benefits to using 3D printing for manufacturing:

Design Freedom

3D printing allows designers to create complex and intricate designs that were previously impossible to produce using traditional manufacturing methods. This opens up new possibilities for creativity and innovation.

Cost-Effective

3D printing can be a cost-effective alternative to traditional manufacturing methods, particularly for small production runs. The process eliminates the need for expensive molds or tooling, which can be significant cost savings.

Customization

3D printing allows for customization of products to meet the client’s specifications. This can be particularly useful for medical devices or other specialized products.

Speed

3D printing can be a faster alternative to traditional manufacturing methods. The process eliminates the need for manual labor, which can significantly reduce production time.

Customizable and Personalized Designs

With the help of 3D printing, the fashion industry now allows you to create your own unique and personalized designs.

This revolutionary technology has transformed how we approach fashion, offering limitless possibilities for customization and self-expression.

You no longer have to settle for mass-produced clothing; now, you can design garments that embody your individuality and style.

3D printing enables you to experiment with intricate patterns, unconventional shapes, and innovative materials, pushing the boundaries of traditional fashion.

Whether you’re looking to design a one-of-a-kind dress for a special occasion or create accessories that showcase your personality, 3D printing empowers you to bring your ideas to life and become a trendsetter in the fashion world.

Embrace this transformative technology and join the fashion movement that celebrates your uniqueness.

Sustainable and Eco-friendly Materials

Continuing the exploration of transformative possibilities in fashion, 3D printing revolutionizes the industry by utilizing sustainable and eco-friendly materials.

This innovative approach reduces waste and promotes a more environmentally conscious mindset within the fashion community.

Here are four reasons why sustainable and eco-friendly materials in 3D printing are changing the game:

- Reduced carbon footprint: Using recycled or bio-based materials, 3D printing minimizes the reliance on traditional manufacturing methods, contributing to pollution and greenhouse gas emissions.

- Material optimization: 3D printing allows for precise material usage, minimizing waste and maximizing efficiency. This approach ensures that resources are used sparingly, making it a sustainable alternative to conventional production methods.

- Biodegradability: Many 3D printing materials are biodegradable, meaning they can naturally break down over time without causing harm to the environment.

- Upcycling possibilities: 3D printing enables the use of recycled materials, turning waste into valuable resources. This promotes a circular economy by reducing the need for new raw materials and extending the lifespan of existing ones.

Embracing sustainable and eco-friendly materials through 3D printing contributes to a more responsible fashion industry and empowers individuals to make conscious choices that align with their values.

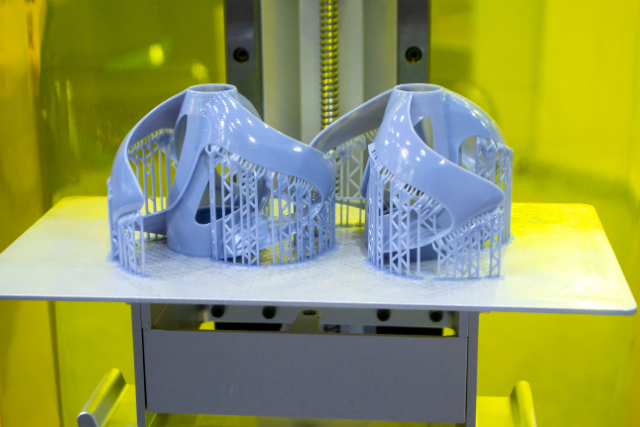

Complex and Intricate Accessories

3D printing revolutionizes the fashion industry by utilizing sustainable materials and consistently enabling the creation of complex accessories.

This technology pushes the boundaries of traditional fashion, allowing designers to bring their wildest accessory concepts to life.

From intricate jewellery pieces to avant-garde headpieces, 3D printing offers unique and intricate designs that allow individuals to express their style like never before.

The precision and accuracy of this technology reshape the way we think about accessories, offering a world of possibilities for fashion enthusiasts.

Whether it’s a statement necklace or a one-of-a-kind clutch, 3D printing opens up a realm of intricate details and complex structures that were once unimaginable.

Rapid Prototyping and Iterative Design Process

With the advent of 3D printing, designers can now utilize rapid prototyping and an iterative design process to bring their innovative ideas to life.

It allows fashion designers to quickly iterate on their designs, leading to faster development and refinement.

Rapid prototyping and iterative design revolutionize fashion in four key ways.

Efficiency: 3D printing accelerates the design process, reducing the time and effort required for creating prototypes and samples.

Cost-effectiveness: By eliminating the need for traditional manufacturing methods and materials, 3D printing reduces production costs, making fashion more accessible.

Customization: Rapid prototyping enables designers to easily create personalized garments and accessories that cater to individual tastes and preferences.

Sustainability: 3D printing minimizes waste by producing only what is necessary, promoting an environmentally friendly approach to fashion production.

Democratization of Fashion and Accessibility

Revolutionize fashion by embracing the democratization and accessibility brought forth by 3D printing.

No longer limited to the elite few, fashion becomes inclusive and allows for individual expression through personalized, custom-made garments.

With 3D printing, anyone can design and produce clothing tailored to their measurements and style preferences, empowering them to become designers.

This transformative technology eliminates traditional manufacturing processes and associated costs, breaking down barriers and fostering a sense of belonging and self-expression for all.

Frequently Asked Questions

What Are Some Examples of Customizable and Personalized Designs Can Be Created Using 3D Printing in Fashion?

Using 3D printing in fashion opens up a world of possibilities for personalized and customizable designs. Whether it’s intricate patterns or unique accessories, this technology allows individuals to showcase their individuality and make a stylish statement.

With the freedom to explore different designs and elevate their fashion game, people can embrace their unique style and stand out.

3D printing in fashion is crucial in creating bespoke pieces that perfectly fit an individual’s preferences and body shape.

How Does the Use of Sustainable and Eco-Friendly Materials in 3D Printing Contribute to the Fashion Industry’s Efforts Toward Sustainability?

Using sustainable and eco-friendly materials in 3D printing allows the fashion industry to contribute significantly to sustainability.

Individuals can actively participate in this movement by reducing waste and carbon footprints and helping create a more environmentally conscious future.

This innovative approach to manufacturing aligns with the industry’s efforts to embrace sustainability, as it offers a crucial and effective solution to address environmental concerns.

What Are Some Challenges Faced When Creating Complex and Intricate Accessories Through 3D Printing in Fashion?

Creating complex and intricate accessories through 3D printing in fashion can pose challenges. Issues may arise with structural integrity, material limitations, and design complexity.

However, these obstacles can be overcome with innovative techniques and continuous experimentation.

With careful consideration and exploration, 3D printing in fashion can be elevated to new heights, embracing the freedom of creativity and offering solace to designers seeking unique and essential solutions.

How Does the Rapid Prototyping and Iterative Design Process Enabled by 3D Printing Benefit the Fashion Industry?

The fashion industry greatly benefits from the rapid prototyping and iterative design process made possible by 3D printing.

This technology allows designers to quickly test and refine their creations, keeping them ahead of trends and enabling the delivery of innovative and personalized fashion products to customers.

With 3D printing, designers can explore new possibilities and elevate their designs, embracing the freedom to experiment and discover unique solutions that meet the industry’s ever-changing demands.

In What Ways Does 3D Printing Contribute to the Democratization of Fashion and Increased Accessibility for Consumers?

3D printing contributes to the democratization of fashion by increasing accessibility for consumers. It allows for customizing and creating unique designs, empowering individuals to express their individuality and find a sense of belonging in the fashion industry.

Consumers can explore new possibilities and discover a whole new realm of fashion possibilities. This innovative solution elevates the fashion landscape and allows consumers to embrace their style.

Conclusion

3D printing has transformed the fashion industry by pushing boundaries and setting new trends. The customizable and personalized designs have empowered individuals to express their unique style.

The use of sustainable materials contributes to a more eco-friendly approach. With the ability to create intricate accessories, 3D printing opens up endless possibilities for designers.

The rapid prototyping process shortens the time to bring fashion concepts to life, democratizing fashion and making it more accessible.