Let us explore how 3D printing can transform your operations, maximizing efficiency and driving innovation.

With enhanced design flexibility, accelerated prototyping, and reduced manufacturing costs, you can easily customize and personalize vehicles like never before.

Embrace the future of spare parts production and stay ahead of the competition in the automotive industry with 3D printing technology.

Table of Contents

Key Takeaways

- 3D printing technology enhances design flexibility and customization in automotive manufacturing, allowing for the creation of intricate and tailor-made components.

- Rapid prototyping capabilities of 3D printing accelerate the development process, enabling faster design iterations and validation.

- 3D printing reduces manufacturing costs by minimizing waste, eliminating the need for expensive tooling, and streamlining the supply chain through on-demand production.

- The revolutionized production of spare parts through 3D printing enables on-demand production of complex parts, reducing waste and storage requirements.

Enhancing Design Flexibility

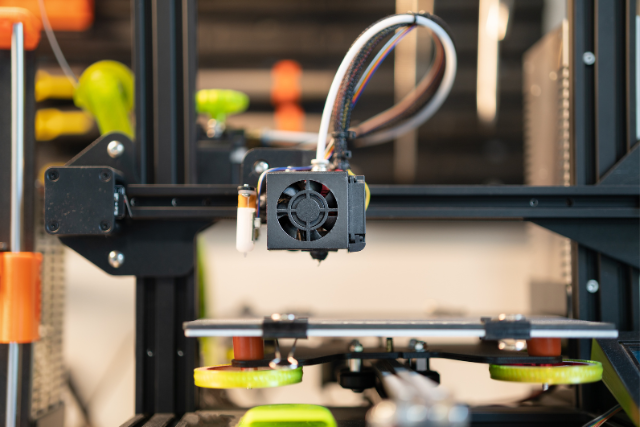

To enhance design flexibility in automotive manufacturing, 3D printing technology can be utilized. This technology allows for creating intricate and customizable parts, enabling easy prototyping and design iteration.

With 3D printing, complex geometries and intricate details that were previously unachievable can now be produced, providing unprecedented freedom to automotive designers.

3D printing allows for the customization of components, optimizing performance and efficiency. It also simplifies assembly by enabling the integration of multiple parts into a single component.

Accelerating the Process

Regarding expediting the prototyping process, 3D printing offers numerous advantages. With its rapid prototyping capabilities, you can swiftly transform design concepts into tangible prototypes, saving valuable time in the development cycle.

This enables more design iterations and faster feedback loops, resulting in enhanced product quality and expedited time to market.

Rapid Prototyping Benefits

Accelerating the prototyping process in automotive manufacturing can be achieved by utilizing rapid prototyping.

This approach offers various advantages that enhance the efficiency of automotive prototyping, enabling faster and more effective design realization. Here are three key benefits of rapid prototyping:

- Time savings: Rapid prototyping allows for the quick production of physical prototypes, reducing the time required for design iterations and testing.

- Cost reduction: By adopting rapid prototyping, costs associated with traditional prototyping methods, such as tooling and material waste, can be minimized.

- Design validation: With rapid prototyping, automotive designs can be physically evaluated and validated early in the development process, enabling the identification of potential issues and necessary modifications before mass production.

Time-Saving Design Iterations

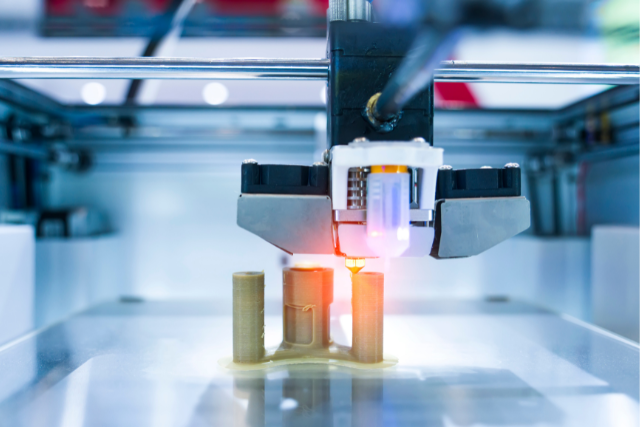

Rapid prototyping in automotive manufacturing can significantly accelerate the design iteration process, saving time and enhancing efficiency.

Traditional methods like manual modeling and mold making can be complex and time-consuming, leading to delays.

However, 3D printing technology allows for the quick production of physical prototypes from digital designs, enabling rapid iteration and testing of different concepts.

To speed up product launches, we can shorten the time for each design iteration during the development process.

The ease of modifying and iterating designs facilitates better collaboration and feedback loops, improving product quality and customer satisfaction.

Rapid prototyping with 3D printing is revolutionizing the automotive industry by enabling faster and more effective design iterations.

Reducing Manufacturing Costs

3D printing technology offers significant cost benefits for manufacturers, particularly in reducing production expenses.

One advantage is material savings, as 3D printing allows for precise and on-demand production, minimizing waste and eliminating the need for excess materials.

Manufacturers can enjoy tooling cost reduction since 3D printing eliminates the requirement for expensive molds and tooling.

Another benefit is a streamlined supply chain, where manufacturers can produce parts in-house, reducing reliance on external suppliers and cutting transportation and inventory costs.

These advantages translate into substantial cost savings for manufacturers in automotive manufacturing, resulting in more affordable vehicles for consumers.

This technology enhances efficiency and provides manufacturers with a competitive advantage in the industry.

Enabling Customization and Personalization

3D printing technology offers a significant advantage in automotive manufacturing by enabling customization and personalization.

Unlike traditional methods, which are time-consuming and costly, 3D printing allows for the creation of unique and tailored components effortlessly.

This technology empowers automotive manufacturers to provide personalized options to customers, allowing them to choose specific designs, colors, and features for their vehicles.

Whether it’s a custom dashboard, personalized interior trim, or a one-of-a-kind exterior design, 3D printing fulfills individual preferences.

This level of customization not only enhances customer satisfaction but also fosters a sense of belonging and ownership.

With the power of 3D printing, automotive manufacturers can meet the growing demand for personalized vehicles while maintaining efficiency and reducing costs.

Improving Supply Chain Management

To improve supply chain management in automotive manufacturing, consider utilizing 3D printing technology.

Integrating this innovative solution into your supply chain, you can achieve streamlined production, reduced logistics costs, and improved flexibility.

Streamlined Production: 3D printing enables on-demand manufacturing, minimizing excessive inventory and reducing lead times.

Reduced Logistics Costs: By producing parts locally with 3D printing, long-distance shipping and transportation costs can be eliminated.

Improved Flexibility: Rapid prototyping and quick adaptation to design changes with 3D printing minimize the risk of supply chain disruptions.

Incorporating 3D printing into your supply chain management empowers you to create a more efficient and agile manufacturing process.

This technology allows you to optimize production, minimize costs, and respond quickly to market demands, ultimately achieving greater success in the automotive industry.

Revolutionizing Spare Parts Production

Revolutionize spare parts production by embracing the power of 3D printing technology in your automotive manufacturing process.

With 3D printing, you can produce spare parts on demand, eliminating the need for large inventories and reducing costs.

Traditional methods involve time-consuming and expensive processes like tooling and molding, but 3D printing allows for quickly creating complex parts without specialized tooling.

This technology also enables the production of spare parts in small quantities, reducing waste and storage requirements.

By adopting 3D printing, streamline your spare parts production, ensuring availability when needed while optimizing efficiency and reducing costs.

Frequently Asked Questions

Can 3D Printing Be Used for Large-Scale Manufacturing in the Automotive Industry?

3D printing can indeed be utilized for large-scale manufacturing in the automotive industry. It offers various advantages, such as enhanced efficiency through reduced production time and costs.

It enables greater design flexibility and the creation of intricate and lightweight components. This innovative technology has the potential to revolutionize the automotive manufacturing process, providing a more streamlined and cost-effective solution.

What Are the Limitations of 3D Printing When It Comes to Automotive Manufacturing?

The limitations of 3D printing in automotive manufacturing encompass material constraints, restricted production scale, and lengthier production times.

Technology advancements and process optimization are addressing these challenges to enhance efficiency.

By exploring innovative solutions and embracing newfound freedom, the automotive industry can elevate its manufacturing capabilities whilst overcoming the limitations of 3D printing.

Discovering and exploring alternative approaches that can contribute to the ever-evolving landscape of automotive manufacturing is crucial.

How Does 3D Printing Impact the Overall Sustainability of the Automotive Manufacturing Process?

3D printing has a significant positive impact on the overall sustainability of the automotive manufacturing process. It minimizes waste by utilizing only the necessary materials and enables the production of intricate designs that enhance fuel efficiency and reduce emissions.

By embracing this innovative technology, the automotive industry can explore new avenues for sustainable manufacturing practices.

Additionally, 3D printing offers the freedom to discover and explore whimsical designs that can further elevate the sustainability of the automotive sector. It is crucial for the industry to embrace this essential solution to achieve a more sustainable future.

What Are the Challenges Faced in Implementing 3D Printing Technology in the Automotive Industry?

Implementing 3D printing in the automotive industry poses challenges. Overcoming material compatibility, production speed, and cost-effectiveness is crucial. By addressing these obstacles, we can fully harness the transformative potential of this technology.

Are There Any Regulatory or Safety Concerns Associated With Using 3D Printed Parts in Automobiles?

There may be concerns regarding regulations and safety when using 3D-printed automobile parts. Ensuring these parts meet industry standards and undergo rigorous testing is crucial for their reliability and performance. It is important to address potential risks and take necessary precautions to ensure the safety of using these parts in automobiles.

Conclusion

Adopting 3D printing technology in automotive manufacturing has revolutionized the industry by maximizing efficiency in various aspects.

This technology enhances design flexibility, accelerates the prototyping process, reduces manufacturing costs, enables customization and personalization, and improves supply chain management.

It has also revolutionized spare parts production, increasing convenience and reducing vehicle owners’ downtime.

Overall, 3D printing has become an indispensable tool in the automotive manufacturing.