Have you ever wondered how 3D printing could transform your small business?

As you venture into the world of 3D printing, it’s crucial to grasp the basics: understanding the technology, selecting the right printer, choosing suitable materials, designing for 3D printing, and mastering maintenance and troubleshooting.

Let’s start by demystifying the technology set to revolutionize manufacturing and design for small businesses.

By getting these fundamentals right, you’ll save time and resources and unlock a world of innovation and creativity.

Isn’t it time you discovered how these elements work together to bring your ideas to life?

Key Takeaways

- Evaluate printer technology and build volume to ensure it meets your business needs.

- Choose materials that match your project’s requirements for durability and finish.

- Design with 3D printing constraints in mind to optimize for efficiency and detail.

- Perform regular maintenance and utilize troubleshooting resources to maintain print quality.

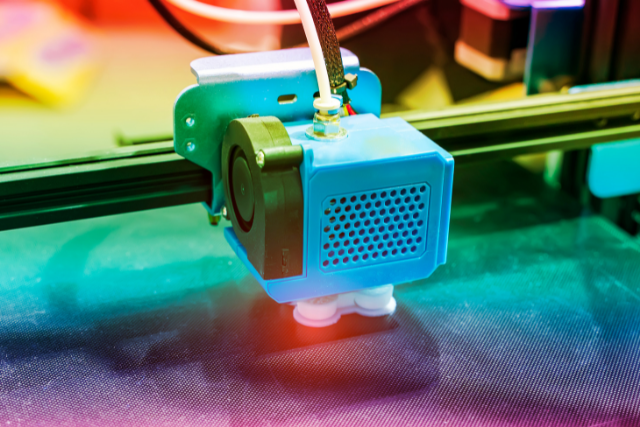

Understanding 3D Printing Technology

At its core, 3D printing technology allows you to turn digital designs into tangible objects with precision and ease. Imagine having the power to create anything you’ve designed on a computer, from intricate jewellery to functional machine parts, right at your fingertips.

This isn’t just a dream; it’s the reality that 3D printing offers.

Traditional manufacturing constraints do not limit you. There is no need for expensive moulds or tools. You start with a digital model, and layer by layer; your design comes to life. It’s as if you’re sculpting with pixels, not clay.

This process, known as additive manufacturing, builds objects from the ground up, minimizing waste and allowing for complex geometries that would be otherwise impossible or prohibitively expensive with conventional methods.

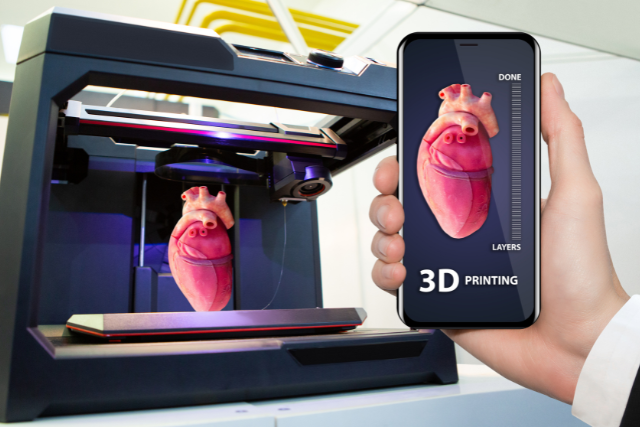

What’s truly liberating is the accessibility and flexibility 3D printing brings. Whether you’re a small business owner looking to prototype a new product or an artist keen on bringing your visions into the physical world, 3D printing opens up a world of possibilities.

It’s not just about what you can create; it’s about how swiftly and efficiently you can bring ideas to life, breaking down barriers to innovation and design.

Selecting the Right 3D Printer

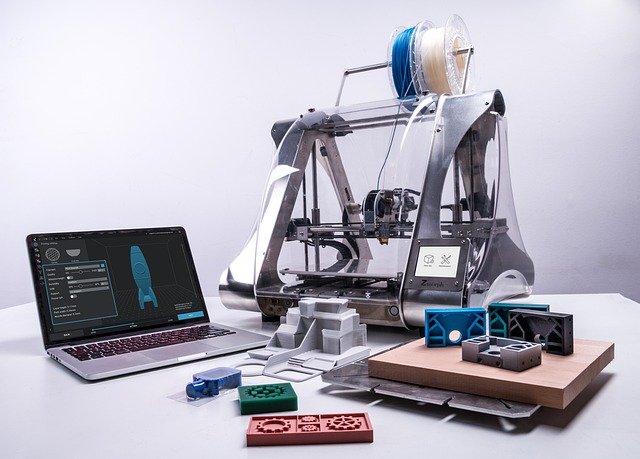

Choosing the right 3D printer for your small business is crucial in shaping how your ideas come to life. You’re not just buying a machine; you’re unlocking the potential for your products and designs.

It’s essential to consider what you need from a 3D printer. Do you value speed, detail, or maybe a balance of both? Understanding this will guide your decision.

First off, look into the printer’s technology. Fused deposition modelling (FDM) printers are widely used and cost-effective, making them a great starting point for many businesses.

If your work demands finer detail, resin-based printers could be the way to go, even though they’re a bit pricier.

Next, consider the printer’s build volume. It’s all about what you plan to print. Larger models need a printer with a spacious build area but don’t overspend on a large printer if your products are generally small.

Lastly, ease of use and support are key. A printer with a supportive community and accessible customer service can save you countless headaches. You’re not just choosing a printer; you’re choosing a partner in your creative journey.

So, take your time, research, and pick a printer that aligns with your business’s aspirations.

Choosing Suitable Materials

Now that you’ve selected the right 3D printer, it’s crucial to consider the materials that will best bring your projects to life. The world of 3D printing materials can be overwhelming, but you’re about to break it down, making your choice as straightforward as possible.

First off, understand the basics. Plastics like PLA and ABS are known for their ease of use and versatility. PLA is biodegradable and perfect for prototypes or non-functional items.

However, ABS offers more strength and heat resistance, which is ideal for parts that will face tougher conditions.

Then, there’s PETG, a robust material that combines PLA’s ease of use with ABS’s strength. It’s great for functional parts that need to be durable yet somewhat flexible.

Don’t forget, there’s more than just plastic. Metals, resins, and even wood composites can be used, each offering unique properties for specialized applications. Metals are perfect for high-strength, durable parts, while resins provide exceptional detail for intricate models.

Choosing the right material isn’t just about what your printer can handle; it’s about what your project needs to succeed. Consider durability, flexibility, and the finish you desire. With this knowledge, you can make informed decisions that liberate your creative potential.

Designing for 3D Printing

Before you start working on 3D printing, it’s crucial to master the art of designing models tailored for this innovative process.

Designing with 3D printing in mind means understanding the limitations and possibilities of your printer. You’re not just creating a design; you’re envisioning how it’ll come to life, layer by layer.

It’s about breaking free from traditional manufacturing constraints and unlocking a world of creativity and innovation.

Here’s a quick guide to get you started:

| Consideration | Description |

|---|---|

| Overhangs | Avoid angles greater than 45 degrees to prevent printing issues. |

| Wall Thickness | Ensure walls are thick enough to be printed but not so thick they waste material. |

| Supports | Strategically use supports for complex designs, but remember they’ll need removal. |

| Resolution | Balance between detail and printing time. Higher resolution isn’t always better. |

| Tolerance | Account for slight variations in size due to material shrinkage or expansion. |

Designing for 3D printing isn’t just about the technical aspects; it’s about embracing the freedom to create something unique.

With these guidelines, you’re well on your way to transforming your vision into tangible reality, liberating your creative process from the confines of traditional methods.

Maintenance and Troubleshooting

After mastering the design process for 3D printing, it’s crucial to keep your equipment in top shape to bring those creations to life seamlessly.

Regular maintenance isn’t just a suggestion; it’s necessary if you aim for precision and durability in your prints. Here’s how you can stay on top of it.

First off, you’ve got to keep everything clean. Dust and debris are the archenemies of high-quality 3D prints. A simple brush or a blast of compressed air can work wonders in keeping those tiny particles at bay.

Next up, lubricate the moving parts. Your printer’s axis and rods need smooth movement to function correctly. A drop of sewing machine oil or any light mechanical oil every few months will keep things running like a dream.

Don’t forget about firmware updates. Like your smartphone, your 3D printer thrives on the latest software to stay efficient and introduce new features or fix bugs. Check the manufacturer’s website regularly for updates.

Lastly, troubleshooting is your friend. Got a problem? A forum, a YouTube tutorial, or a guide will likely help you solve it. Embrace these resources; they’re your toolkit for keeping those prints flawless and your business booming.

Conclusion

Now that you’ve got the basics down, you’re ready to get started with 3D printing. Remember, as is mastering your design skills, picking the right printer and materials is crucial.

Don’t forget regular maintenance and being savvy with troubleshooting will save you tons of headaches.

Learn these steps, and you’ll unlock the full potential of 3D printing for your small business, turning your creative ideas into tangible realities. Let’s get printing!